innovative parametric and configurable platform for the production of stainless steel furniture

innovative parametric and configurable platform for the production of stainless steel furniture

What is the EVO.4 platform?

What is the EVO.4 platform?

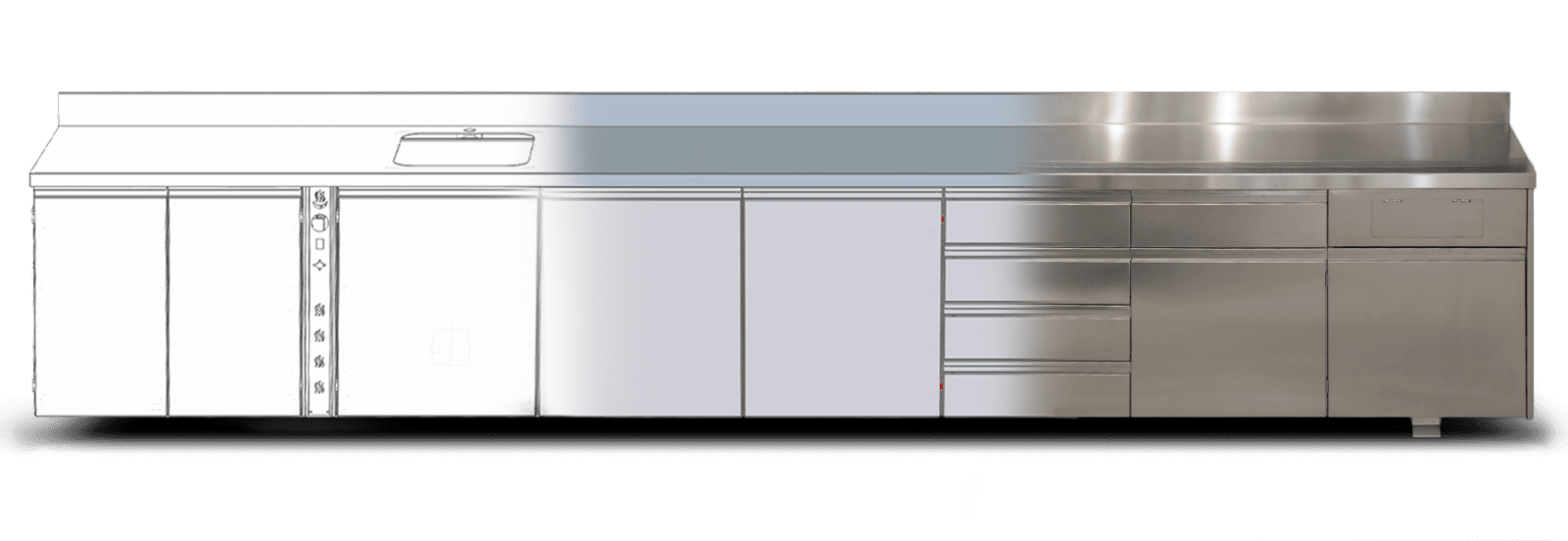

It's AGMA's computer system that processes a library of tried and tested components and construction solutions and automatically generates realistic 3D designs ready for production

PROJECT

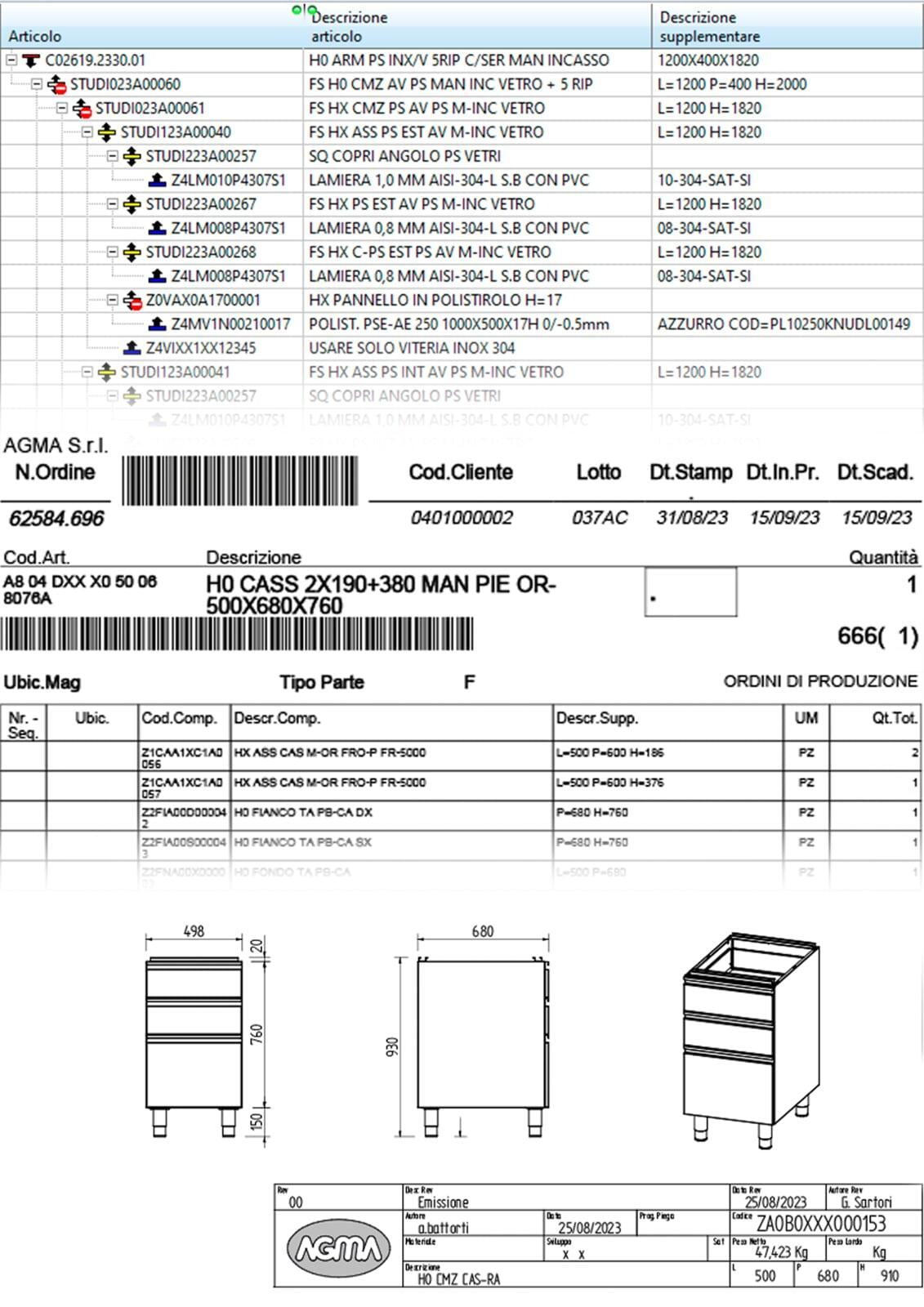

The basis of the Evo4 platform consists of thousands of tested, defined, and parameterised basic components. Such elements already contain all management and production information.

PROCESS

EVO.4 is different from the conventional way of designing and producing!

EVO.4 is different from the conventional way of designing and producing!

- EVO.4 is based on Master projects, each of which contains a collection of parameterised components related to product families, with the information and constraints to configure them into infinite models and variations

- EVO.4 contains solutions for the main professional sectors: food, furniture, healthcare, industry and residential. Sector-specific solutions are standardised and made common, thus ensuring maximum flexibility and quality

- Each finished product is not a static set of elements but the result of an elaboration of 'components as ingredients'. Listed 'usual' furniture codes represent only one of the possible choices that can be activated in Evo4. It is easy to understand how new products and customised solutions become natural and easy to arrange

The innovations of EVO.4:

The innovations of EVO.4:

- EVO.4cancels the distinction between standard and customised: the 'customised' generated by the configurator is always a perfectly standard product... with the difference that it has never been developed before. The 'made-to-measure' therefore remains a solution to be designed from scratch, never made, non-existent. In this case too, it will probably be limited to the design of a few new components to be integrated into the EVO.4 platform.

- EVO.4 is a 'liquid platform', i.e. it can be expanded and enriched at any time with new elements and solutions.

- EVO.4 leaves behind the traditional division of furniture by sector. The specific constructions of the various worlds are mixed and integrated, enabling new solutions and performance always with the highest quality.

- EVO.4 is not a simple product redesign with all possible improvements, but marks a turning point in the stainless steel furniture sector because it addresses and solves complex and innovative processes. The market vision becomes multi-sectoral, with endless possibilities for growth.

- EVO.4 is certainty of result. The product is always elaborated from a true 3D design with the certainty that it will be transferred to production and faithfully realised. The 3D design also allows documentation to be generated for commercial and information purposes.

- EVO.4 does not come out of nowhere, but from AGMA's 35 years of experience in stainless steel furniture construction and the rethinking of previous series from scratch in a parametric and configurable key. Every component has been extensively tested and inspected.

- Cabinets made with EVO.4 have certain and short lead times because the phases of Project - Process - Production - Product are all linked and integrated with each other, cutting downtime.

- AGMA's choices with the EVO.4 platform are based on an in-depth knowledge of the market and the contact and satisfaction of its dealer and manufacturer customers. With EVO.4 AGMA offers absolutely the best solutions in professional furniture at an unbeatable price/quality/delivery time balance!

- EVO.4 represents the certainty of being able to offer customised furnishings, out of the masses and always responding to customers' wishes

And not only that...

And not only that...

- EVO.4furniture is produced using state-of-the-art sheet metal and tube processing machinery. This has given the designers ample freedom to define complex profiles and achieve seamless, robust and hygienic solutions.

- EVO.4 stores every product code in its computer system, identified by a serial number; spare parts and maintenance are not a problem.

- The software solutions used are the most up-to-date and modern available, not only in the design itself, but also in parameterisation and configuration management. They also allow communication between different platforms, cloud collaboration and the tracking of every change and detail.

- Materials and components purchased in EVO.4 are of high quality and all come from highly specialised companies. It could not be otherwise for high-end, durable, traceable and easy-to-maintain furniture.

- Innovation, continuous improvement, identity, evolution and sustainability are at Evo4 concepts full of concrete meanings and witnesses of commitments for the present and the future.

Want to learn more? Book a call with us!

Want to learn more? Book a call with us!