Stainless steel modules

H0 construction

Small and large modules, base units, wall units and tall cabinets belong to this type of construction.

This construction is the basis of most of the furnishings which, for aesthetic, hygienic or functional reasons, must be made exclusively in stainless steel.

TECHNICAL DESCRIPTION

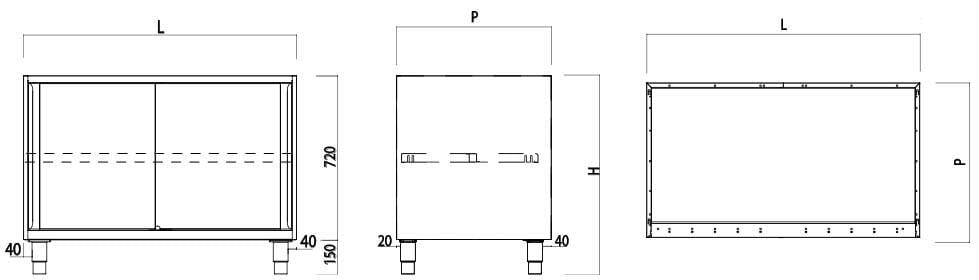

Dimensions:

- Body of furniture based on modularity 72 mm (360/720/1800 mm )

- Standard depths 380/580/680 mm

- Some modules available with reduced depth (530/630 mm)

- Width on base 100 mm

Material:

- Stainless steel AISI 304 scotch brite finishing

Construction features of H0 stainless steel modules:

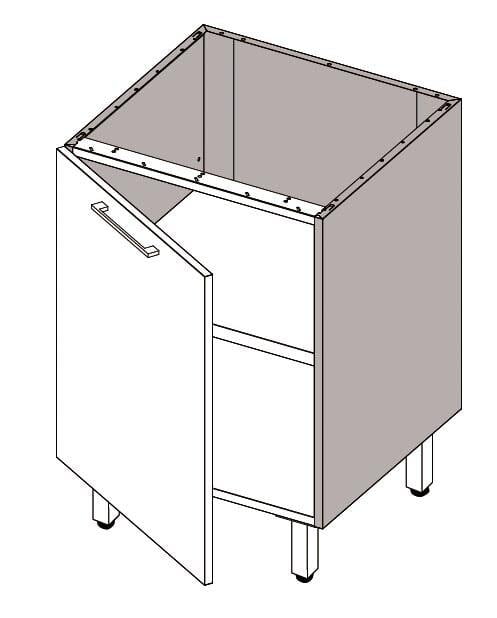

- Finished sides in sight and internal paneling on which shelves and sliders are fixed

- Fully extractable telescopic drawer sliders

- Sides and back joined to the bottom in a structural way

- Feet in glass-filled nylon covered in stainless steel AISI 304, Ø 60 mm H 150 mm. Feet can be removed and replaced with wheels H 134/158

- Double removable stainless steel doors

- Double hinged doors opening 270°, adjustable in 3 directions

- Double sides, 20mm wide

- Fixed in sight back

- Height-adjustable shelves

- Vertical/horizontal integrated by bending handles

- Suitable for plinth with magnetic coupling (which requires square feet 40 x 40 mm)

- Back and front gap of the worktop with respect to the furniture 10 + 10 mm

Main modules:

- Open base: front only or back as well

- Base cabinets with hinged or sliding doors, in case opening two sides

- Sink modules

- Heated cabinets

- Modules with drawer and door

- Drawer sets

- Hoppers for waste management

H0 stainless steel modules can be combined with the following products:

- Wall cabinets

- Tall cabinets

- Columns

To complete the compositions, worktops in stainless steel or other materials can be used.

Why choose Agma?

- The technical project, managed parametrically, allows to easily create customized solutions

- Fast and reliable production times thanks to the industrial organization of AGMA, an ISO 9001 and 14001certified company

- Identification and traceability of all the products supplied